Vertical Mud Type Submerged Megnetic Driven Pumps

Product introduction Vertical Mud Type Submerged Megnetic Driven Pumps Performance range: Diameter: DN25 ~ DN300 flow ra

Send your inquiryDESCRIPTION

Basic Info.

| Position of Pump Shaft | Vertical Pump |

| Transport Package | Wooden Case |

| Specification | API685 standard |

| Trademark | Dalian Kehuan Pump Co., Ltd |

| Origin | Dalian, Liaoning, China |

| HS Code | 8413709990 |

| Production Capacity | 500PC/Year |

Product Description

Product introductionVertical Mud Type Submerged Megnetic Driven Pumps

Performance range:

Diameter: DN25 ~ DN300 flow range: ~ 1200m ³ / h

Head range: ~ 125m Temperature range: ~450 ºC

Power range: 560kw

Structural features:

Single stage, single suction, cantilever structure.

Vertical installation, closed impeller or open impeller.

The pump casing thickness is thickened and the abrasion allowance is large.Add cooling or heating jacket according to working conditions

The rotor housing is filled with inert gas to prevent impurities from entering, and it can be dry running, maintenance costs are very low.

Application

It is suitable for conveying medium with large amount of solid particles, high abrasiveness and high melting point.

Material:

Carbonsteel; chromed steel; austeniticstainlesssteel; duplexsteel; Titanium and Titanium Alloys; Hastelloy C-276 and other special materials; It depends the customer's request

| PARTS NAME | S-6 | A-8 | D-1 | TITANIUM | HAST C276 |

| Casing | Cast steel | 316 AUS | DUPLEX | Ti | HAST C |

| Impeller | 12%CR | 316 AUS | DUPLEX | Ti | HAST C |

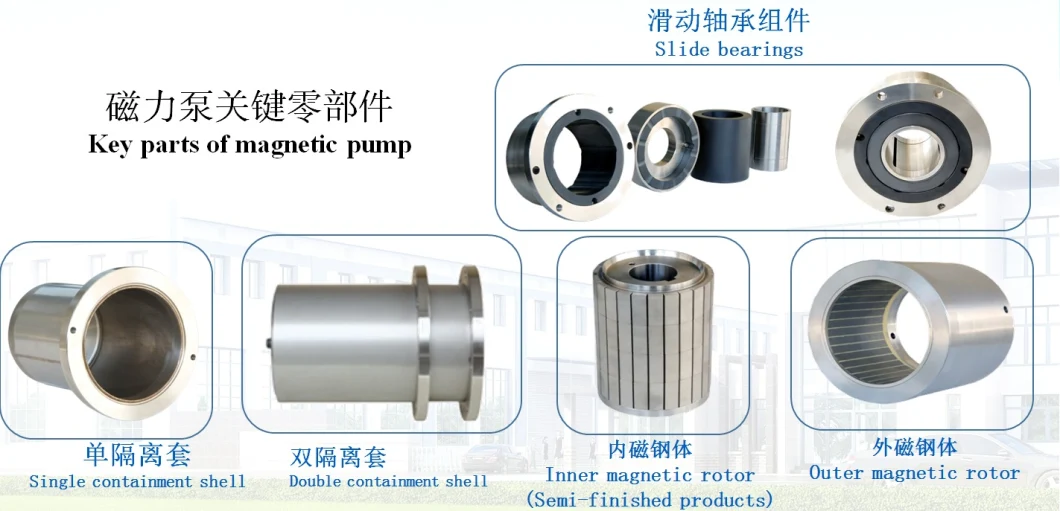

| Containment shell | Hastelloy C276 | Hastelloy C276 | Hastelloy C276 | Hastelloy C276 | Hastelloy C276 |

| Inner magnet rotor | 304/SM2C017 | 316/ | 316/ SM2C017 | Ti /SM2C017 | HAST C/ SM2C017 |

| Pump shaft | 12%CR | 316 AUS | 2205 | Ti | HAST C |

| Slide bearing | 304/SSIC | 316/SSIC | 316/SSIC | Ti/SSIC | HAST C/SSIC |

company profile Dalian Kehuan Pump Co.,Ltd was established in 2002 ,Registered capital:50 million RMB. The factory covers an area of 20,000 square meters. and the workshop area is more than 10,000 square meters.There are 150 employees, and many of the main management and technical personnel are from well-known pump companies. Sales in the last three years have remained within the range of 100 to 120 million.Kehuan Pumps specializes in the research and development, design, manufacturing and continuous improvement of high level magnetic pumps. The original intention of the general manager is to believe that technology and environmental protection are the major trends and future themes. We advocate: Enjoy technology and protect the environment. This is also the origin of the company name. The reasons why we did not choose a canned motor pump and chose a magnetic pump mainly consider several aspects:1. The magnetic pump has a flexible structure and has good interchangeability with ordinary centrifugal pumps.2. Convenient inspection and maintenance, low maintenance cost, and energy saving than canned motor pump.3. At present, domestic magnetic pumps cannot be used as large pumps. Foreign magnetic pumps account for much higher proportions than canned motor pumps, so we need to reinforce them. First, there are a lot of South magnet pumps manufacture focus on PVDF magnetic pumps and low-standard metal magnetic pumps (design standards JB/T 7742 and HG/T 2730) .They are limited by their own capabilities and cannot cope with many working conditions. Second: Some joint ventures have not fully engaged in the development of magnetic pump. For example, H company, which has been in the Chinese market for many years, mainly promotes canned motor pumps in order to cater to the preferences of the Chinese market. The magnetic pump, which should have been vigorously developed, has not been updated for decades. Their magnetic pumps can only be used in simple working conditions which is less than 132kw. Kehuan pump must make a comprehensive breakthrough in the status quo of magnetic pumps (such as High power, High temperature, Mud, Easy vaporization, High melting point, etc.) Design framework: We use European advanced hydraulic model; Design standards according to American petroleum institute standard API685. High standard material application: Permanent magnet (Sm2Co17, Temp. -196~450ºC), Sliding bearing (SSIC), Containment shell(HC-276), Rolling bearing (SKF/NSK), Coupling (Wuxi Chuang ming) /German KTR), Electric motor (Nan yang/Jiamusi).We are well-known in domestic market because of our High quality products and reliable quality assurance system, high efficiency performance and excellent solutions.

We also have long-term and stable cooperation with foreign customers. Like European, Russia, Chile, India and so on.

*If you have any questions about our products,please contact me as soon as possible at your convenience. Looking forward to your requiry.Thank you for your concern.